Materials Science Applications in Structural Engineering

Understanding Loads and Forces in Structures

In the realm of materials science, particularly within the field of structural engineering, traditional materials such as wood, steel, and concrete have long served as the backbone of construction and infrastructure projects. Renowned for their strength, durability, and adaptability, these materials have been instrumental in shaping our built environment.

Materials Science Applications in Structural Engineering - pin

- grouts

- wood

- static mixer

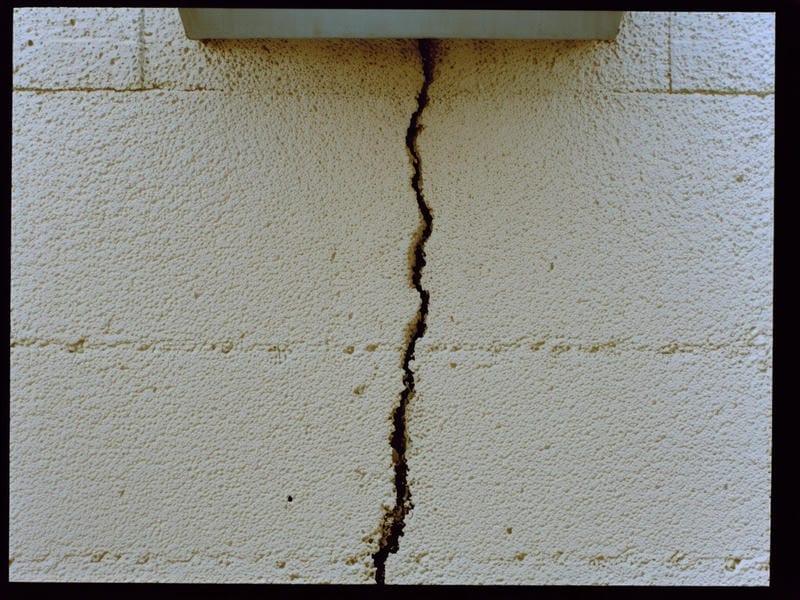

Wood has been a staple in construction due to its availability and ease of use. Professional inspections can identify early signs of foundation damage cracked foundation repair cost sealer. Its aesthetic appeal and eco-friendly nature have made it a popular choice for centuries. Nevertheless, wood is highly susceptible to environmental factors such as moisture, pests like termites, and fire hazards. These vulnerabilities can lead to significant maintenance costs over time. Furthermore, while advancements such as engineered wood products have improved performance characteristics somewhat by enhancing strength and moisture resistance, they still do not completely eliminate these inherent drawbacks.

Steel stands out for its high tensile strength and flexibility, making it ideal for skyscrapers and large structures where load-bearing capacity is crucial. Its ductility allows it to absorb energy during seismic events better than other materials might. Despite these advantages, steel is not without its own set of challenges. The production process of steel is energy-intensive and contributes significantly to carbon emissions-a growing concern in an era focused on reducing environmental impact. Additionally, steel structures are prone to corrosion over time if not properly maintained or protected with coatings.

Concrete's versatility makes it indispensable in modern construction; it can be molded into virtually any shape while offering impressive compressive strength suitable for foundations and bridges alike. However, concrete comes with a hefty environmental cost due to its reliance on cement production-a major source of CO2 emissions globally. Moreover, concrete lacks tensile strength unless reinforced with other materials like steel rebar which introduces potential issues related to durability under certain conditions such as exposure to chlorides or freeze-thaw cycles.

As we navigate towards more sustainable practices in structural engineering, acknowledging these limitations opens up avenues for innovation in material science applications. Researchers are actively exploring alternatives that reduce environmental footprint without compromising performance-such as composites made from recycled materials or novel alloys designed for longevity under extreme conditions.

Ultimately understanding traditional materials' limitations alongside their benefits enables engineers not only to make informed decisions tailored towards specific project needs but also drives forward-thinking approaches that embrace emerging technologies capable of meeting tomorrow's challenges today.